Filtration Systems manufactures a wide range of fiberglass filter elements for natural gas purification. Our media is molded into seamless tubes and reinforced with phenolic resin (a clear improvement over the “pipe insulation” of some competitors). Natural gas is often dirty, wet and corrosive, and gas filters have to withstand liquid shock and pipe scale abrasion. Our cartridges use high-efficiency seamless fiberglass tubes, reinforced with spiral-stitched center tubes for high collapse resistance. Cross references to PECO, Peerless, King Tool, Jonell, Flo-Line and Banner.

Since these filters are often installed before large compressors, they must be designed to resist vibration, pulsation, and abrasion from pipe scale and liquid shock.

Our center tubes feature a spiral seam construction for high collapse resistance, and the metal is plated for corrosion resistance. The end caps are attached to the middle and center tube with a high strength adhesive.

We use a polyester core wrap to prevent media migration as fiberglass fibers are very abrasive. Unfortunately some of our competitors don't use center wrap!

For applications where iron sulfide is a problem, we offer a polyester membrane core.

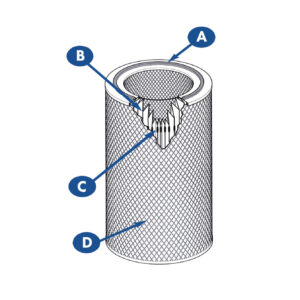

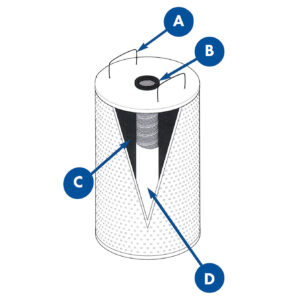

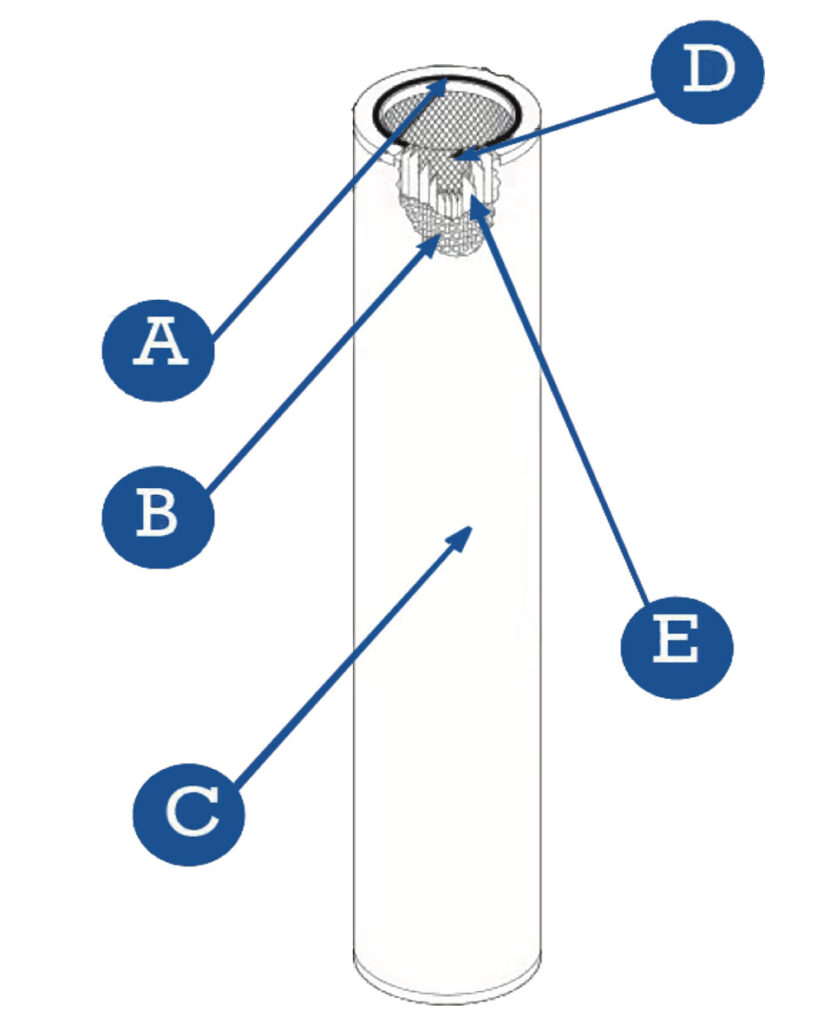

technical summary

- TO Tinned metal end caps are bonded to the center tube for added strength. Choice of Buna-N or Viton gaskets.

- B. Double louvered center tubes provide low flow restriction. Made in-house for excellent availability and cost control.

- C. Spunbonded polyester core wrap prevents media migration. Available membrane wrap provides 0.3 micron protection.

- D. 6# seamless molded fiberglass media removes >1u particles and coalesces liquids for clean, dry natural gas.